|

This topic shows you how to:

Before you begin, ensure that you have:

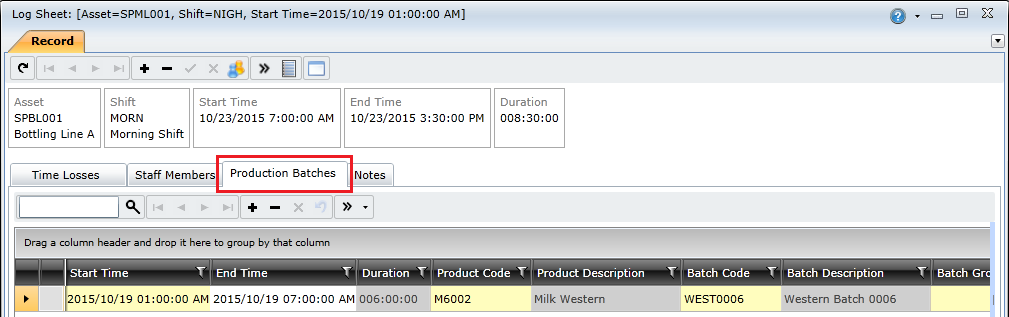

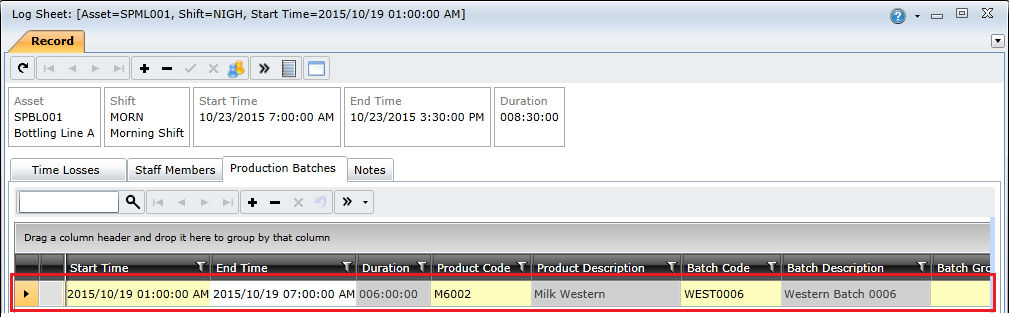

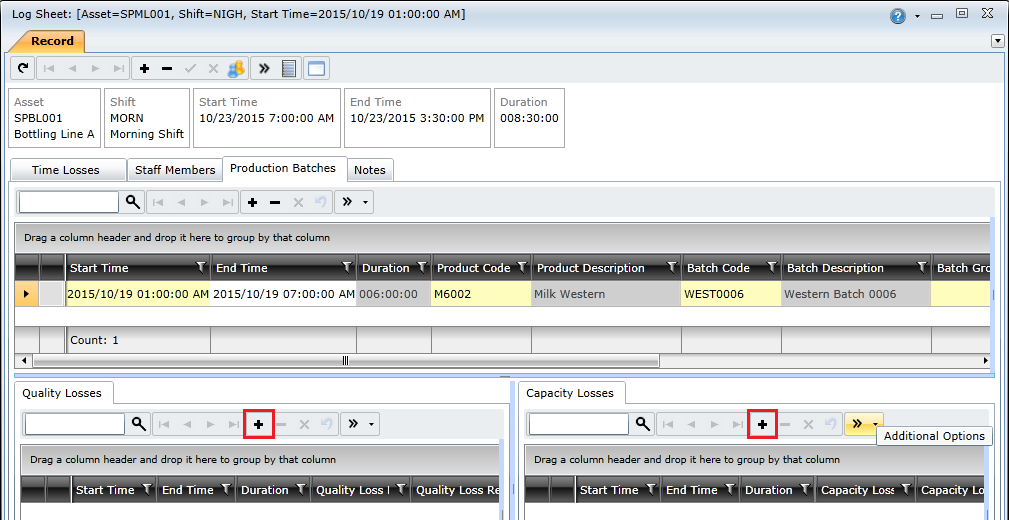

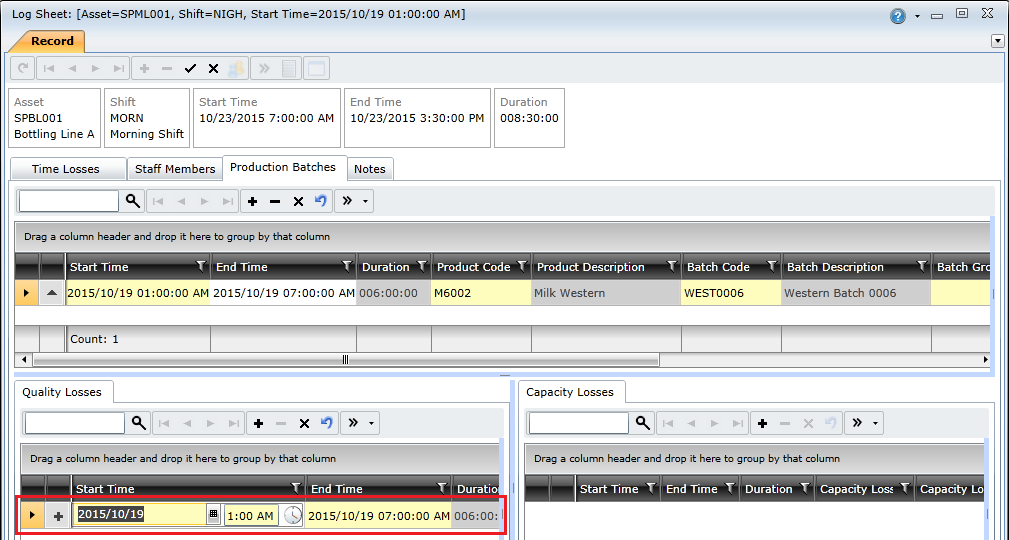

Adding capacity or quality loss reasons enable you to specify the reasons for losses experienced within specific production batches.

To add a capacity OR quality loss reason to a production batch, you need to do the following:

) button in the relevant section below the production batches grid.

) button in the relevant section below the production batches grid.

|

Field |

Description |

|

Start Time |

The date and time the loss started. |

|

End Time |

The date and time the loss ended. |

|

Quality\Capacity Loss Reason |

The type of loss that was experienced. |

|

Units Lost |

The number of units lost as a result of the loss. |

Note: Quality and capacity losses can be configured with user defined fields (UDFs). UDFs are displayed as the last columns in the relevant grid.

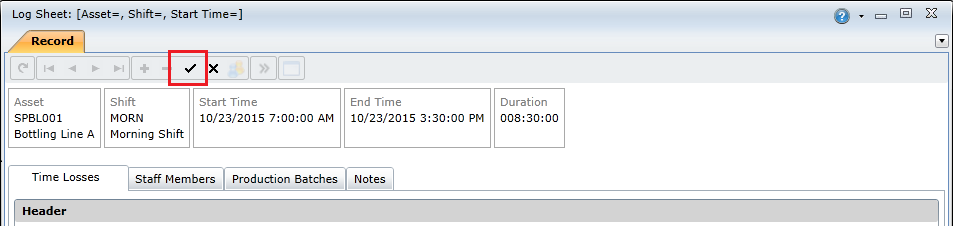

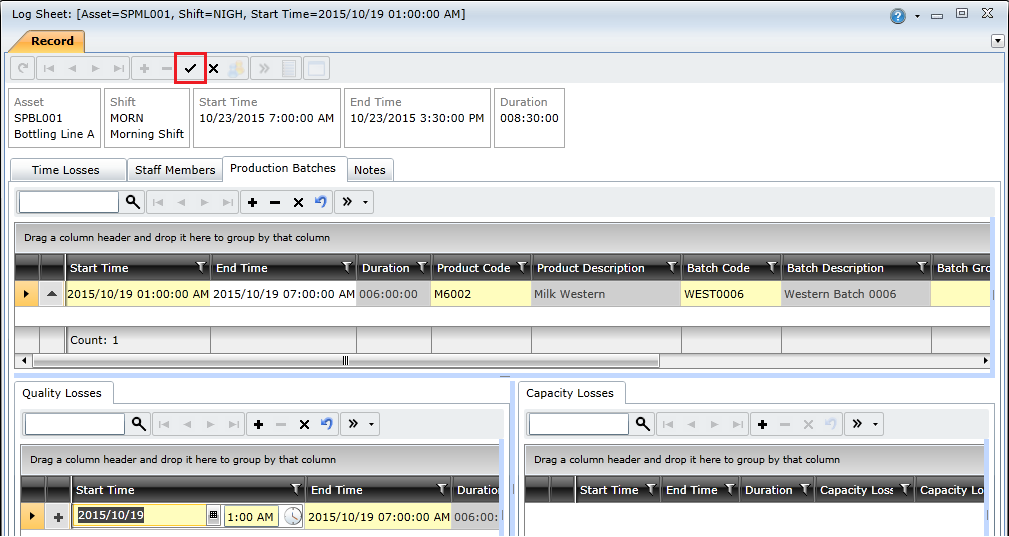

Click the Save Changes ( ) button to save the loss reason.

) button to save the loss reason.

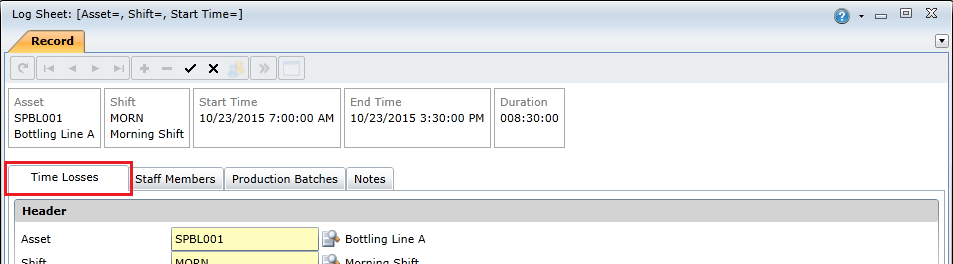

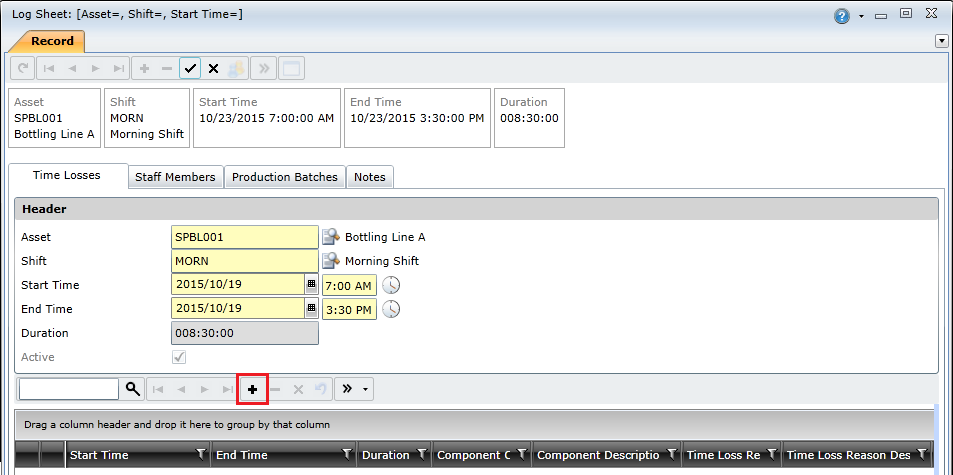

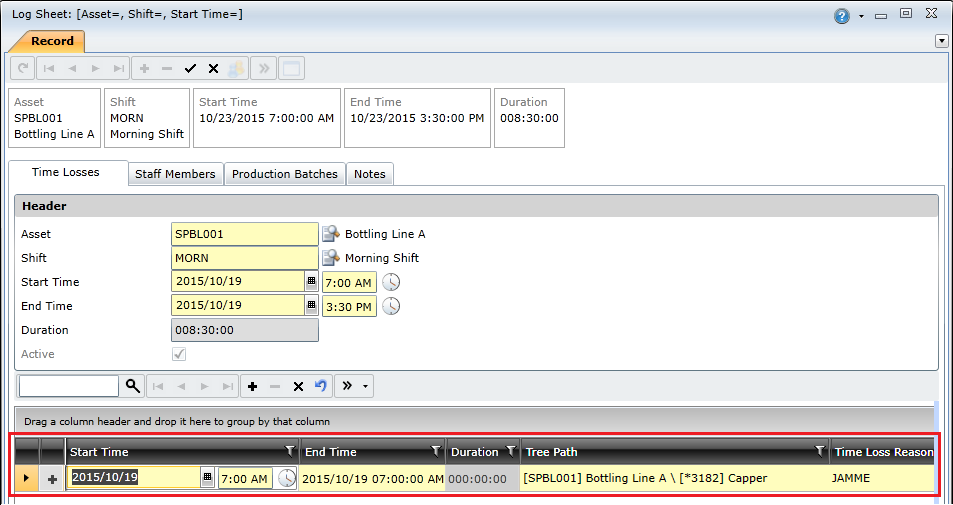

Adding time loss reasons to a log sheet enables you to specify the reasons for asset downtime during a specific shift.

To add a time loss reason to a log sheet, you need to do the following:

) button on the toolbar to add a new loss reason.

) button on the toolbar to add a new loss reason.

|

Field |

Description |

|

Start\End Time |

The date and time the loss started and ended. Notes:

|

|

Tree Path |

Select the asset or component that failed and resulted in the time loss. Notes:

|

|

Time Loss Reason Code |

The loss that occurred. Notes:

|

|

Work Order Code |

The work order for the repairs required to correct the problem. Either , double-click the field to create a new work order, OR click the Lookup ( |

Note: Time losses can be configured with user defined fields (UDFs). UDFs are displayed as the last columns in the time losses grid.

) button to save the loss reason.

) button to save the loss reason.