|

To add a new production batch, you need to do the following:

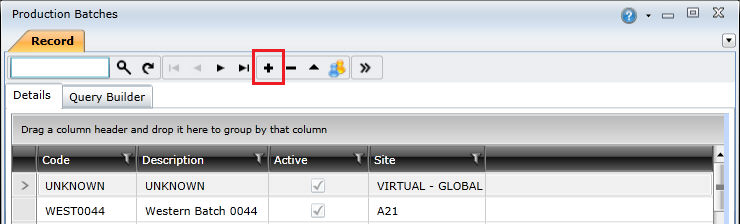

Select Main Menu → Performance Manager → Product Configuration → Production Batches → Show Browse Window ( ) to open the browse window.

) to open the browse window.

Click the Insert New Record ( ) button to open the Production Batch edit window.

) button to open the Production Batch edit window.

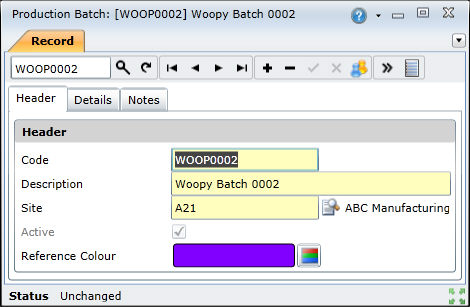

Complete the fields on the Header tab.

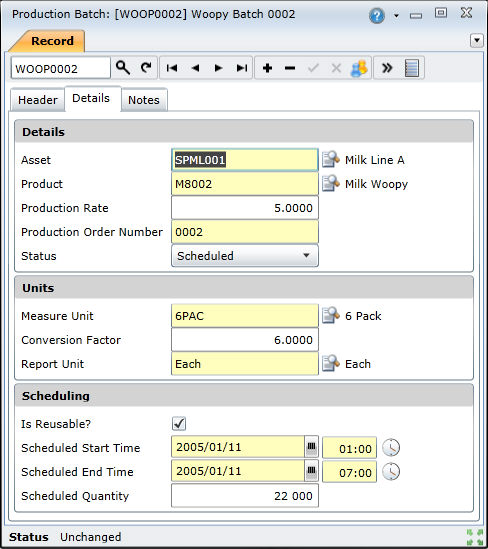

Complete the fields on the Details tab.

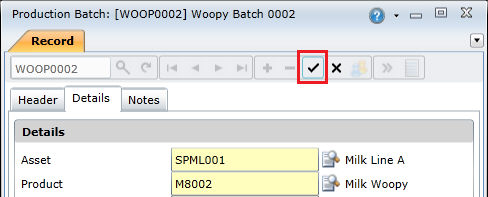

Click the Save Changes ( ) button to create the production batch.

) button to create the production batch.

The Production Batches edit window consists of two tabs:

The Header tab includes the following fields:

| Field | Description |

| Code | A unique code that identifies the production batch in On Key. |

| Description | A full description of the production batch. |

| Site | The site at which the production batch is manufactured or assembled. |

| Active | Indicates whether the production batch is available for use in On Key. |

| Reference Colour | Specifies the colour used to identify this production batch in reports. |

The Details tab includes the following fields:

| Field | Description |

|

Details |

|

| Asset | The asset used to manufacture or assemble the products that make up the production batch. |

| Product | The product that is to be manufactured or assembled in the production batch. Note: The lookup list only displays products that have been linked to the selected asset or asset type. |

| Production Rate | The rate at which the asset is able to manufacture or assemble the product included in the production batch. The rate is specified as the number of units per second, and it defaults to the product's production rate. For example, if an asset takes 4 seconds to manufacture a product, the Production Rate is 0.25. |

| Production Order Number | The unique order number used to identify the production batch. |

| Status | Indicates the production batch's current state. For example, the status could be used to indicate whether the production batch is scheduled, in progress, or complete. |

| Units | |

| Measure Unit | The unit of measurement used to measure or count production batches for reporting purposes. For example, for liquid production batches the measure unit would be litres or millilitres. |

| Conversion Factor | The number that the Measure Unit must be multiplied by to calculate the Report Unit. This is only required if the Measure Unit and Report Unit are different. For example, if the Measure Unit is grams and the Report Unit is kilograms, the Conversion Rate is 1000. |

| Report Unit | The unit used to measure or count production batch quantities in reports. |

| Scheduling | |

| Is Reusable | Indicates whether the production batch can be reused multiple times. |

| Scheduled Start Time | The date and time that production must start. |

| Scheduled End Time | The date and time that production must end. |

| Scheduled Quantity | The number of product units that will be manufactured or assembled for the production batch. |