Tactical Work Planning Functionality

Purpose

Generate Tasks that are due to be performed within a specific number of days, and create scheduled Work Orders for these Tasks.

Planning

Work planning covers:

Scheduling

Work scheduling covers:

- Creating scheduled Work Orders for selected Proposed Work Orders, and

- Allocating resources and materials to all Work Orders

Tactical work planning

A Planner generates the list of Proposed Work Orders and creates Work Orders for the Sites for which he/she is responsible.

When Proposed Work Orders (for due Tasks) are generated then the filter, split and combination options specified on the Generate Proposed Work Orders Filter window and the scheduling method details on the Asset Task - Scheduling tab determine:

- Which Asset Tasks are due to be done within the specified number of days, and

- How many times the Asset Task is required within the time period.

A Proposed Work Order is generated for:

- Each Asset with Tasks that match the standard filter, split and combination options.

- An Asset with a specific Task Roll Up Point. The Proposed Work Order includes all Tasks that are linked to the specified Task Roll Up Point and meet the filter, split and combination options.

- An Asset with Tasks for a specific Event.

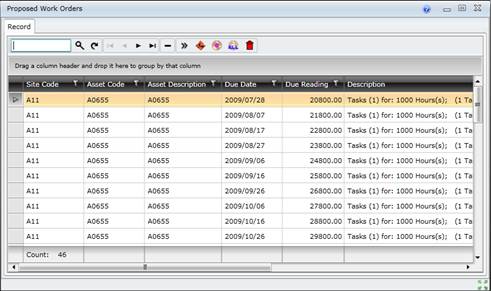

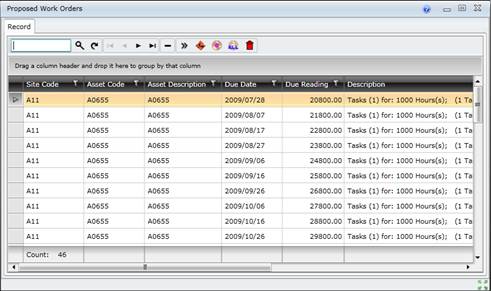

Proposed Work Orders

The Proposed Work Orders are listed on the Proposed Work Orders window.

From the Proposed Work Orders window a user can:

- Drill down to view the Tasks on each Proposed Work Order.

- Create Work Orders for selected Proposed Work Orders.

- Create Work Orders for all Proposed Work Orders.

The Proposed Work Orders browse window appears as follows:

Task Roll Up Points

A Task Roll Up Point is:

- Specified for an Asset in the Asset Tree for which all Tasks (with this Task Roll Up Point) must be grouped and one Work Order generated.

- Configured using the Asset Care Plans - Scheduling Configuration - Task Roll Up Points menu option.

- Specified for each Task that must be executed for an Asset with this Task Roll Up Point. When Proposed Work Orders are generated, the system looks for a parent Asset with same Task Roll Up Point as the Task. If there is no parent Asset with the same Task Roll Up Point in that branch of the Asset Tree, then the Task will appear on a Proposed Work Order for the Asset to which the Task is linked.

Due Date and Scheduling Method

A Task's Due Date is calculated using the Last Done Date or Last Scheduled Date specified on the Asset Task - Dates and Readings tab, depending on the Scheduling Method specified on the Asset Task - Scheduling tab. A Proposed Work Order is generated for each Asset Task with the same Due Date and other standard filter, split and combination options.

- If the Scheduling Method is “Schedule from Last Done” then one Task is scheduled on the Due Date calculated using the Last Done Date.

- If the Scheduling Method is “Schedule from Last Scheduled” then one or more Tasks is scheduled for each Due Date in the specified scheduling period using the Last Scheduled Date.

Suppressed Tasks

Refer to View Suppressed Tasks for Proposed Work Orders.

Business rules

- Tasks with the same standard filter, split and combination options are grouped on a Proposed Work Order.

-

- Asset

- Type of Work

- Due Date, unless the system option Use Grouping Intervals is not zero (on the System Options - Proposed Work Orders tab) and a Grouping Interval has been specified on the Generate Proposed Work Orders Filter - Combination Options tab.

- Scheduling Method, only if Have different Scheduling Methods is not ticked

- (Task) Interval Type only if Are Calendar or Usage based is not ticked

- Meter, only if Are linked to different Meters is not ticked

- Event

- Split Options specified on the Split Options tab

- Tasks with different standard filter, split and combination options are not grouped on the same Proposed Work Order.

- In addition to the above, Tasks will be grouped according to the selected (optional) combination options on the Generate Proposed Work Orders Filter window.

- An Asset Task's Last Scheduled Date is updated when a Work Order is created.

- An Asset Task's Last Done Date is updated when a Work Order is closed and the Task is complete.

- The Last Done Reading or Last Scheduled Reading for a usage based Asset Task is calculated using the Average Daily Rate when the Asset Task's Last Done Date or Last Scheduled Date is updated on the Asset Task - Dates and Readings tab.

For example, if a Meter’s Average Daily Rate is 1000km/day and the Task's Last Scheduled Date is set back 2 days then the Estimated next due reading date is also set back 2 days, and therefore the Meter’s Estimated Next Due Reading is recalculated as the [current Estimated next due reading - 2000kms].

- Labour resources that are required for the Work Order Tasks must be specified as linked detail records for every Asset Task, including Follow Up Tasks, on the Labour for Asset Task window.

- Spares that are required for the Work Order Tasks must be specified as linked detail records for every Asset Task on the Spares for Asset Task window.

- The Work Order's Status is determined as follows.

-

- If the Type of Work specified for the Work Order has an associated Work Order Status on the Type of Work - Details tab then the Work Order's Status is set to the Work Order Status associated with the Type of Work.

If the User does not have user rights to the Work Order Status for the selected Type of Work then the Work Order's Status defaults to “Awaiting Approval”.

- If the User does not have the right to approve the Work Order then the initial Status is set to “Awaiting Approval”.

- If the Type of Work specified for the Work Order does not have an associated Work Order Status on the Type of Work - Details tab then the Work Order's Status is set to the Default Scheduled Work Order Status specified for Work Orders on the System Options - Work tab.

Please note!

- Use the grouping mechanisms to split Tasks on a Proposed Work Order.

As a result separate Proposed Work Orders are generated for Tasks with different Classifications, Responsibilities and Motion Types.

- The default values for system option Days to schedule in advance and system option Use Grouping Intervals are specified on the System Options - Proposed Work Orders tab.

- Days to schedule in advance must be a multiple of the Grouping Interval (days) and is relative to the current date (the date on which the Proposed Work Orders are generated).

- The scheduling period starts on the Starting From date (on the Generate Proposed Work Orders Filter - Combination Options tab) and ends on the Days to schedule in advance after the current date.

- If Grouping Interval (days) and Days to Schedule are not zero then the Tasks that should be performed during the scheduling period are grouped on a Work Order for the applicable grouping interval, as long as they satisfy the standard filter, split and combination options.

- If Grouping Interval (days) is zero then the Tasks that should be performed during the scheduling period are generated for their Estimated Next Due Date, as long as they satisfy the standard filter, split and combination options.

- Proposed Work Orders can be generated as often as required without creating Work Orders because a Task's Last Scheduled Date is only updated when a Work Order is actually created and appears on the list of Work Orders on the Work Orders browse window.

Best practices

- Generate a list of Proposed Work Orders for short periods, for example once a week or once a month, especially when using the “Schedule from Last Scheduled” Scheduling Method.

- Create Work Orders from the list of Proposed Work Orders for short periods, for example once a week or once a month.

What can I do?

These non-standard tools are available in the toolbar on the browse window.

|

|

|

|

|

Open the Generate Proposed Work Orders Filter window, specify filter and grouping criteria, and generate Proposed Work Orders.

|

|

|

Create Work Orders for selected Proposed Work Orders

|

|

|

Create Work Orders for all Proposed Work Orders

|

|

|

Delete Proposed Work Orders.

|

© 2016 Pragma